70 YEARS OF HISTORY

VARESINA STAMPI was founded in Varese in 1950. In 1955, the company moved to its current site in Sumirago (VA). At this stage, the activity moved towards what is its current production activity: die design and hot steel drop forging. The first site was gradually joined in 1987 by a second production facility and in 1989 by yet another facility specialising in the finishing of high-precision mechanical parts.

In 2007, a new plant in Vercelli was set-up with the specific intention of incorporating the missing link in the production chain: a heat treatment facility. The new plant, with more than 100,000 square metres of floor space, quickly became the logistics centre of the industrial group, of which VARESINA STAMPI is a key element. It has enabled the company to further expand its production capacity with the installation of numerous new forging lines. A company history of great depth and in continuous evolution that has made VARESINA STAMPI the fore-father of the POZZI Group, a market-leading industrial group that today boasts a total of three companies and over 450 employees.

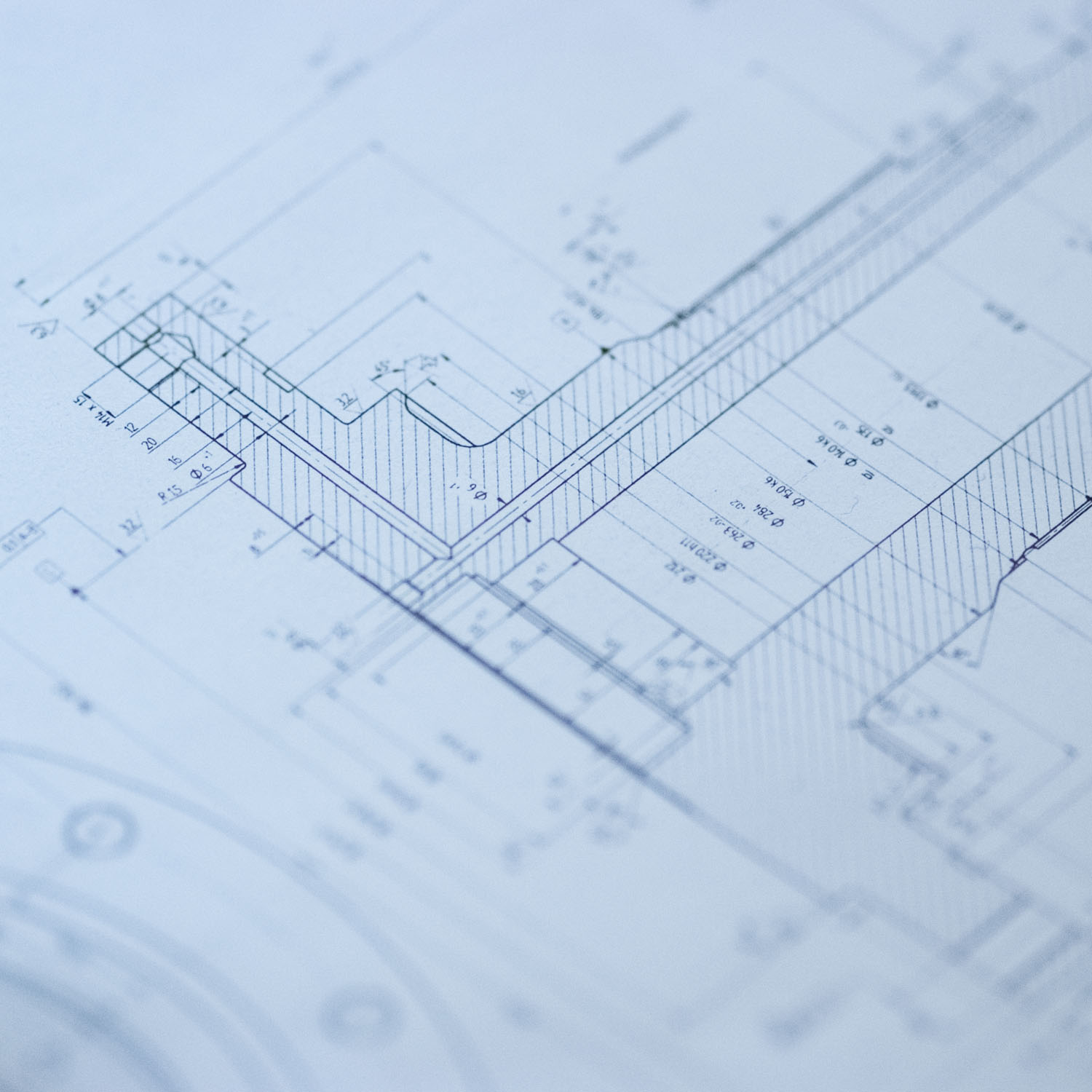

QUALITY, FLEXIBILITY AND SECURITY

Every activity is managed to meet the requirements of all parties involved, be it in product and service quality, corporate sustainability in favour of the environment or safety in the workplace.

The service offered also aims to support the customer in the study phases of the product and the dies necessary for its realisation, suggesting solutions that aim to improve quality, combined with the reduction of energy consumption in the production process.

The high level of management, which is fully computerised from receipt of orders through to processing of deliveries, guarantees a flexibility of intervention that enable customers to find a solution to any executive or programming requirement. Also for this purpose, VARESINA STAMPI manages an internal warehouse whose average stock of steel that is never less than 25-30% of production capacity.

SECTORS OF ACTIVITY

AGRICULTURE

AUTOMOTIVE

CONSTRUCTION

EARTHMOVING MACHINERY

MARINE

RAILWAY

WIND ENERGY

CONTACT US

Varesina Stampi S.p.A.

Management and Works in Sumirago

Via Pozzi, 13 – 21040 Sumirago (VA)

Email: sales@varesina.com

Tel +39.0331.909010