THE FIRST STEP

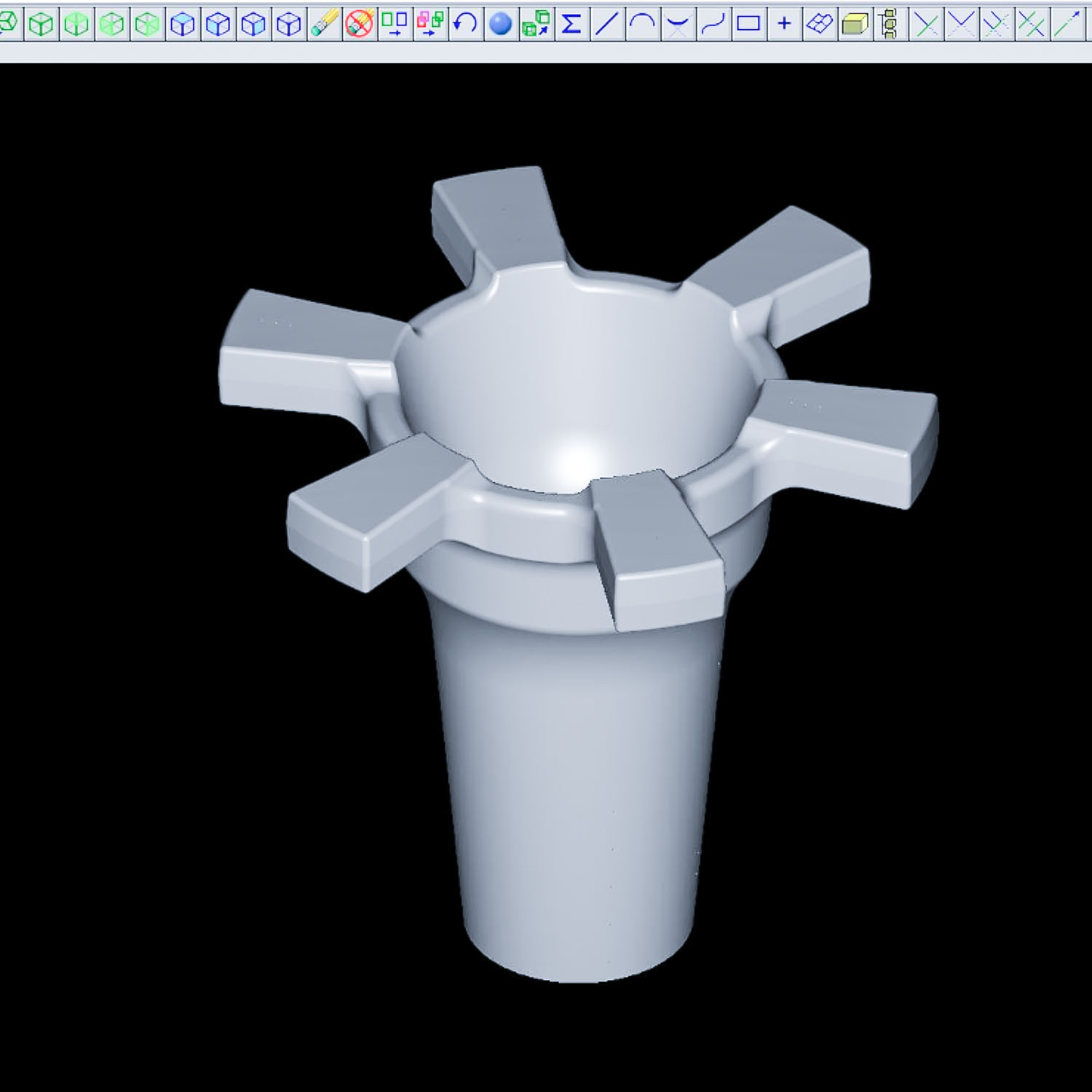

The production process begins with the receipt of the finished part drawing from the customer. Based on this, the outlines of the blank are created.

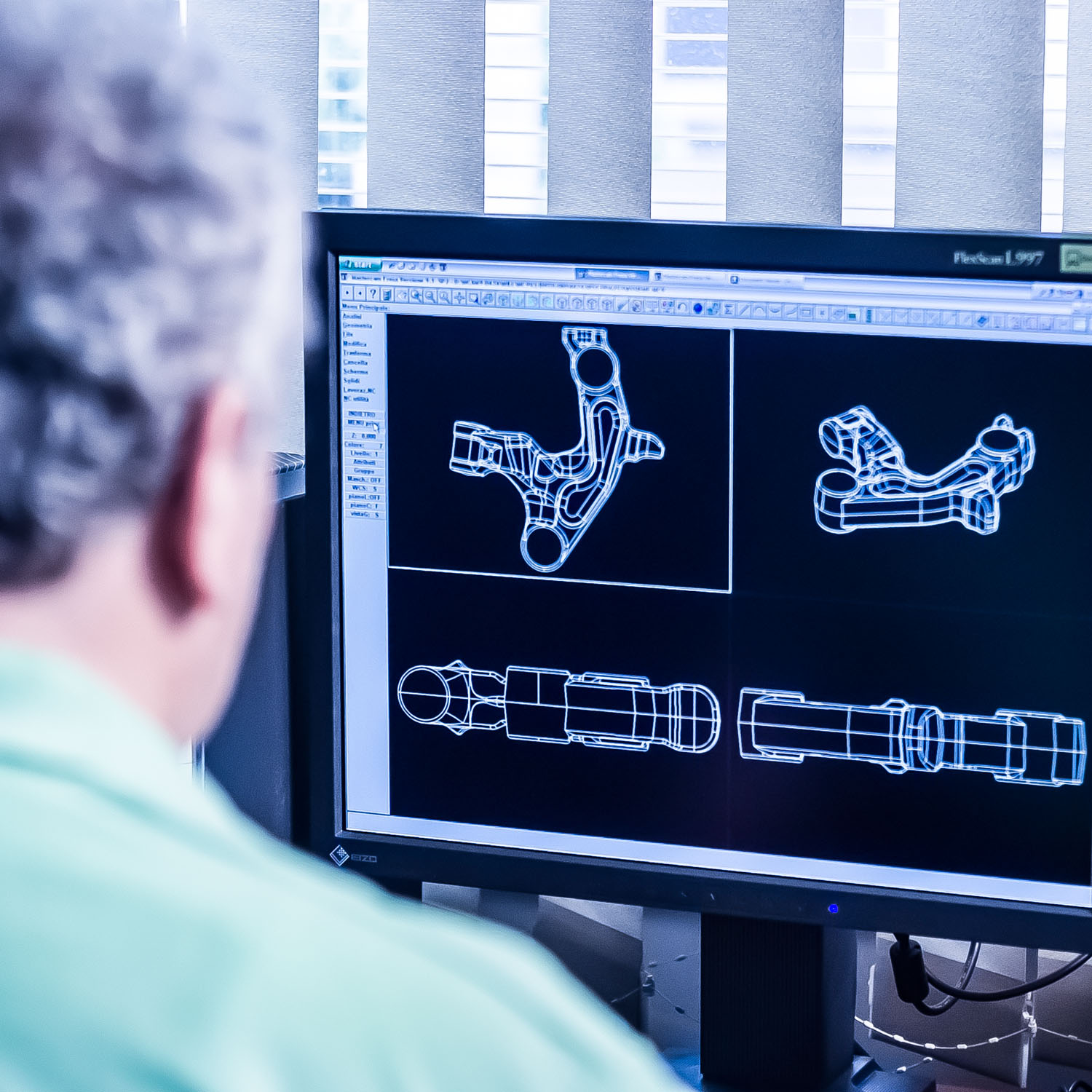

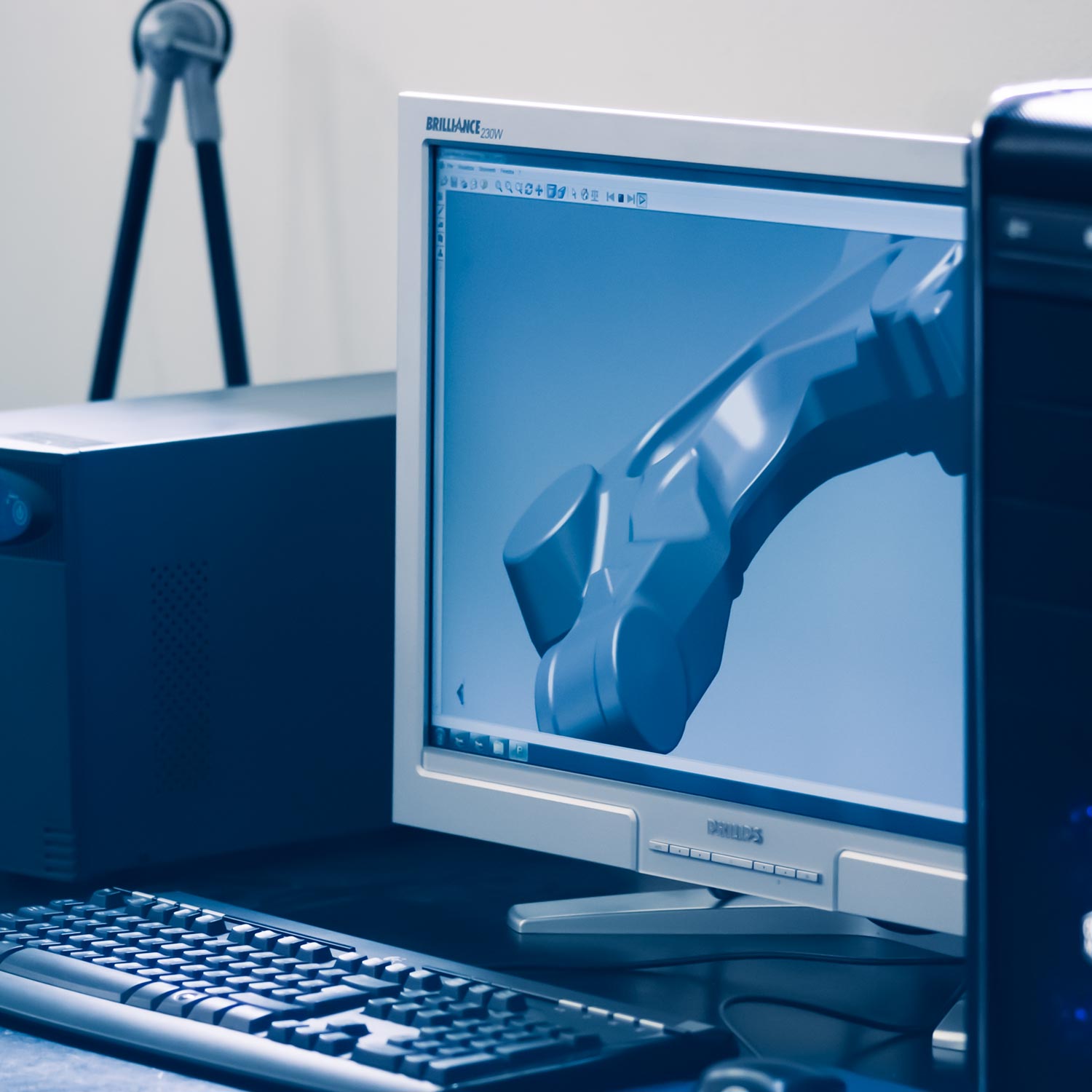

The technical department then proceeds to draw up the basic design part using software such as Solidworks and Mastercam following the rules which will make it compatible with the hot steel drop forging technique.

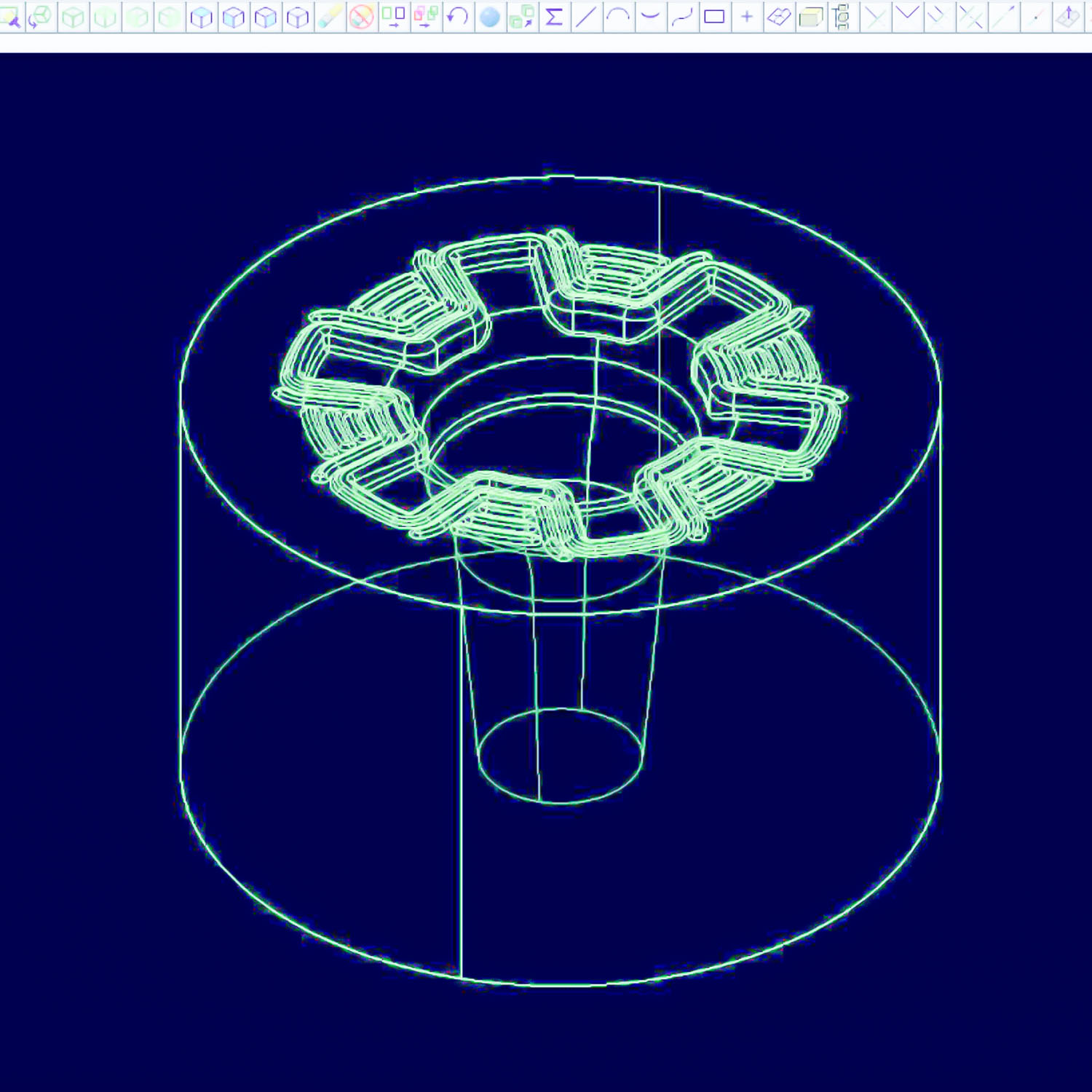

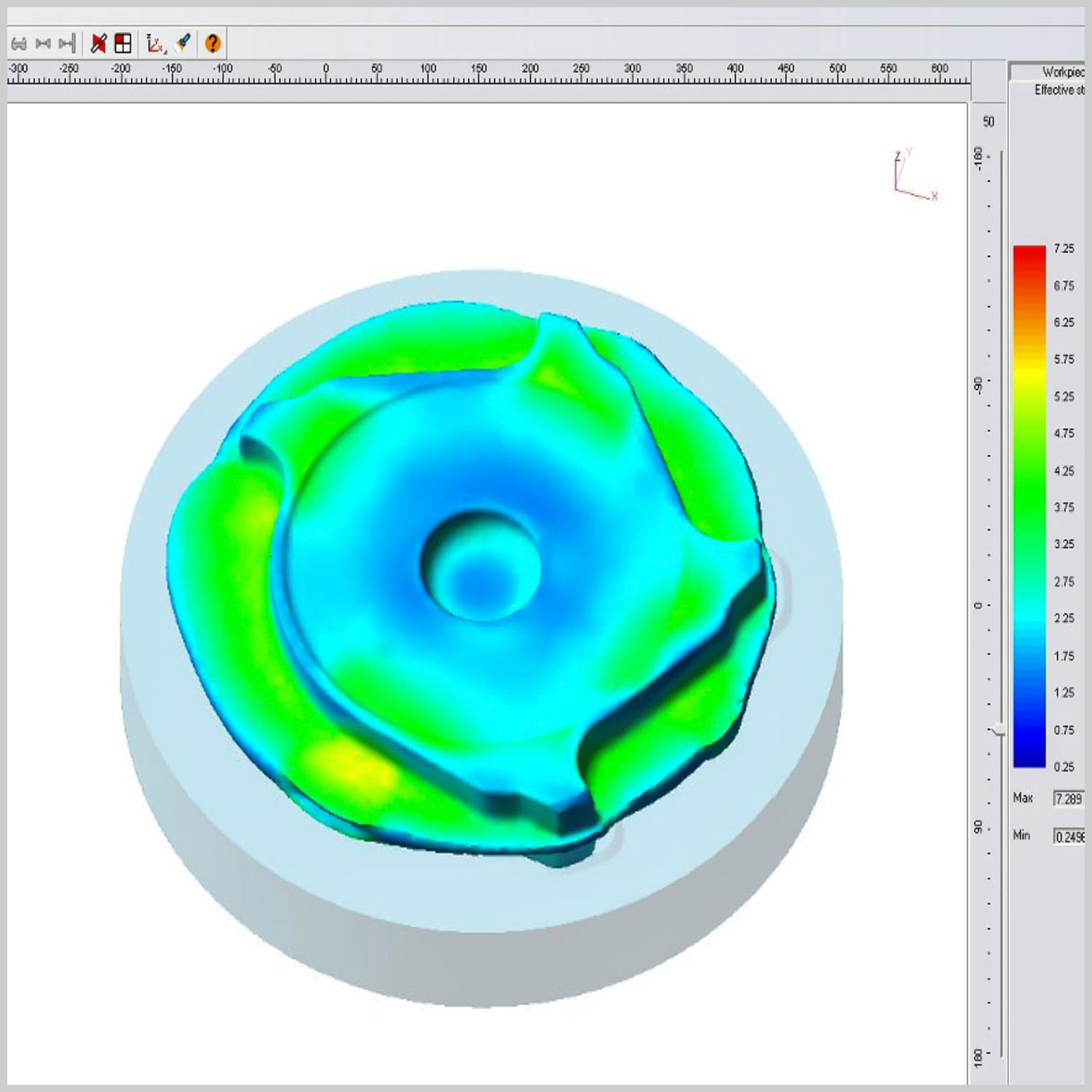

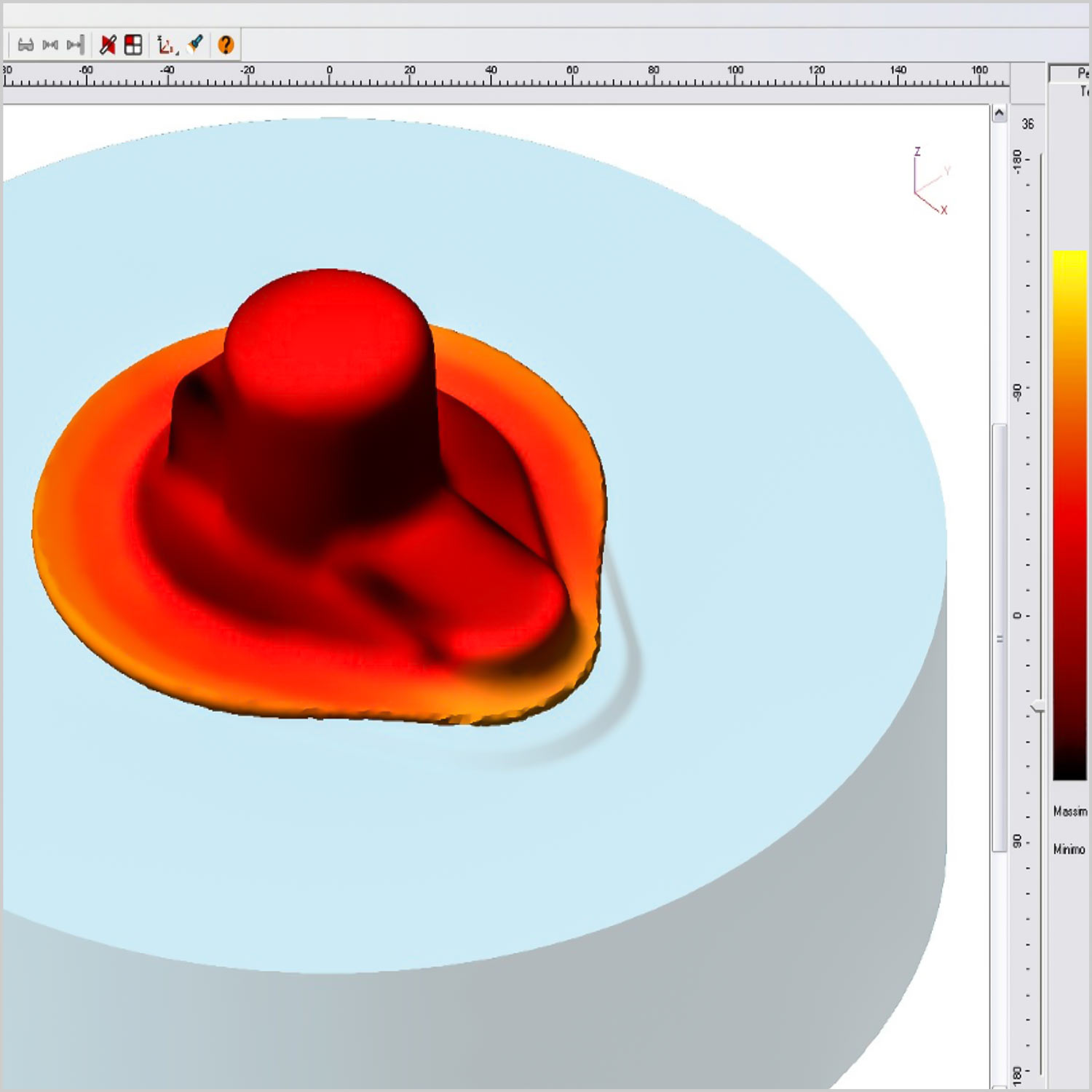

FOOLPROOF SIMULATION

The technical department then processes the drawings, defining the dies and tooling. It then proceeds to simulate the hot steel drop forging process using specific tools such as Qform 2D-3D and Forge 3D to verify the production cycle and achieve a very high quality and error-proof end result.

CONTACT US

Varesina Stampi S.p.A.

Management and Works in Sumirago

Via Pozzi, 13 – 21040 Sumirago (VA)

Email: sales@varesina.com

Tel +39.0331.909010