THE SECOND STEP

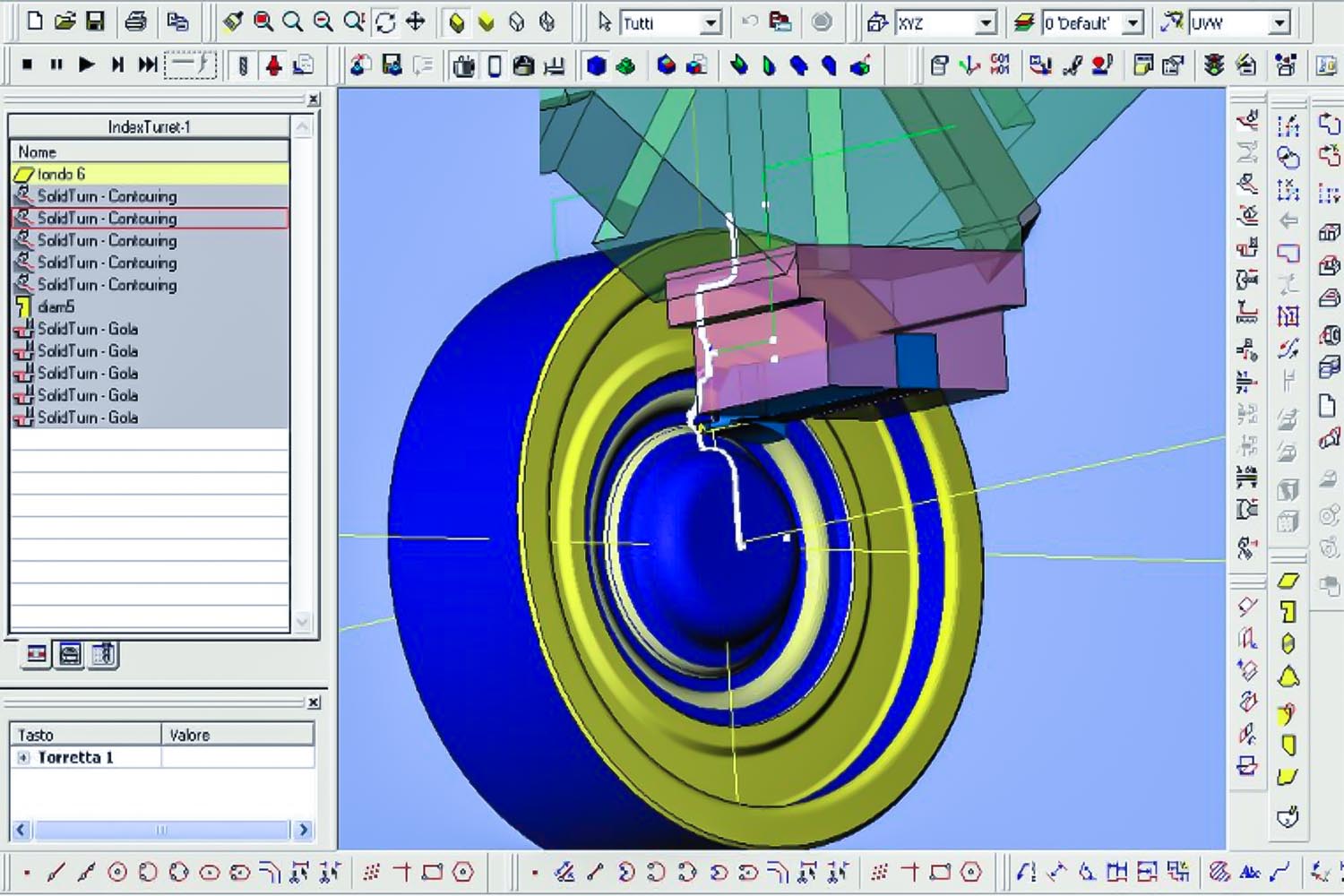

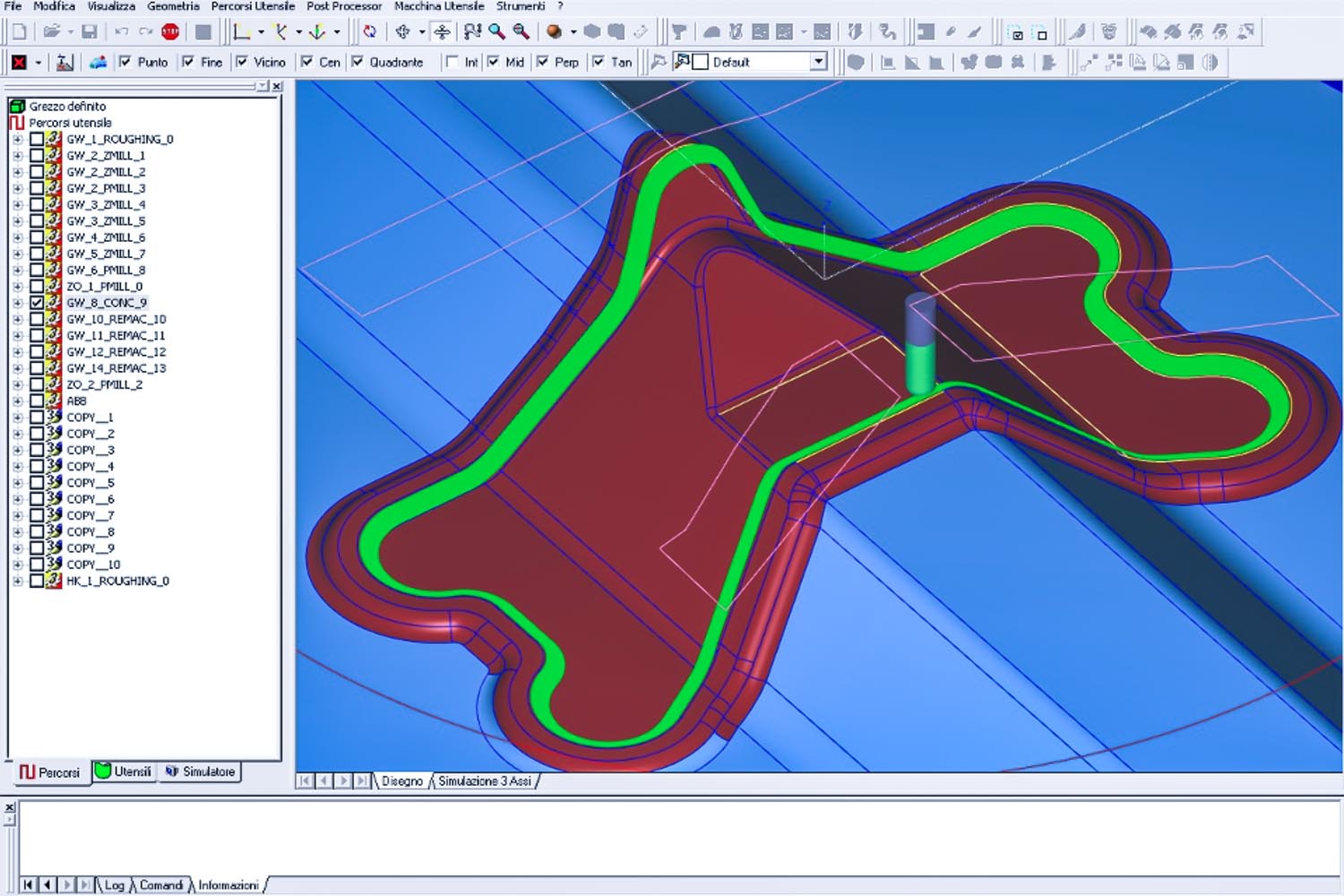

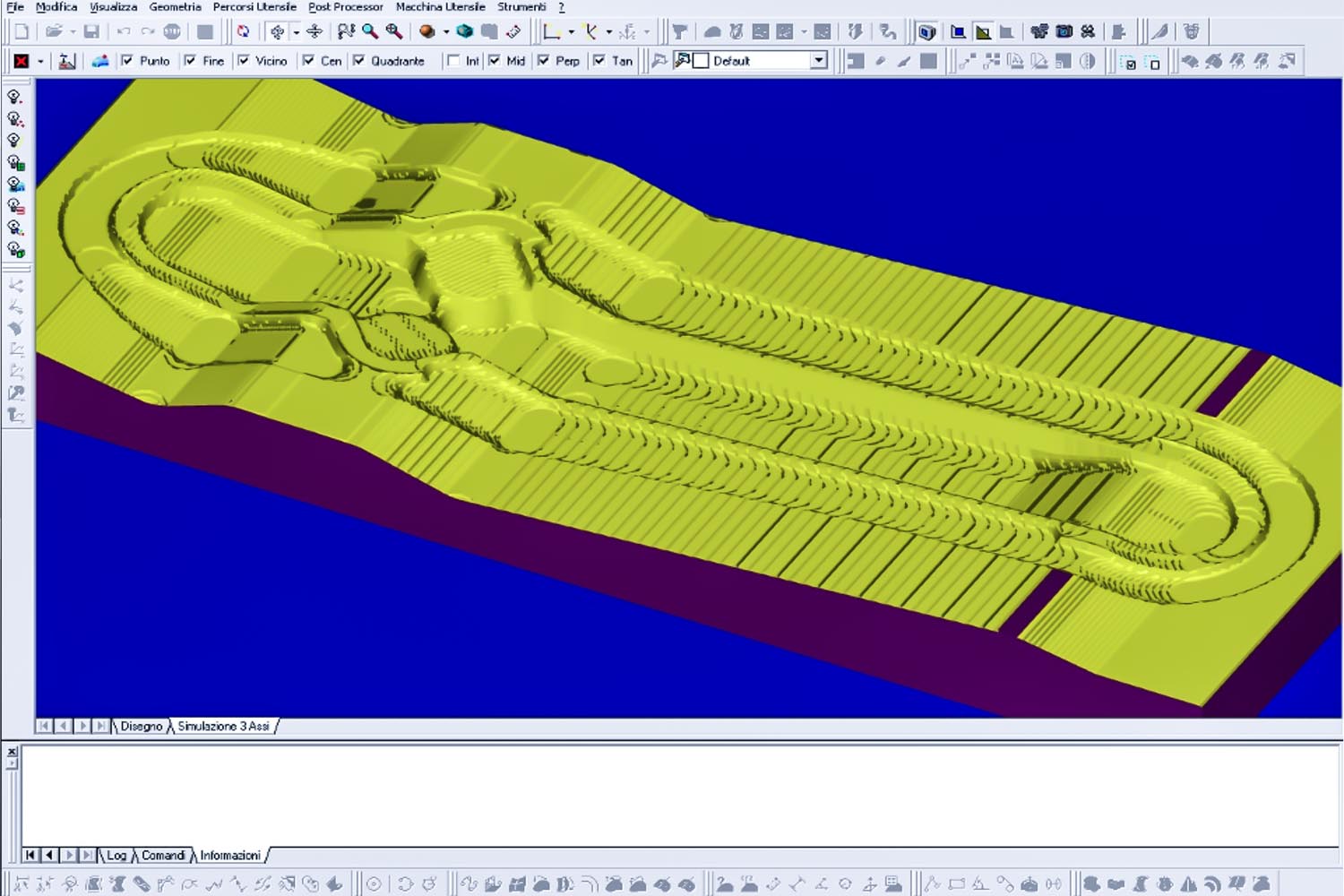

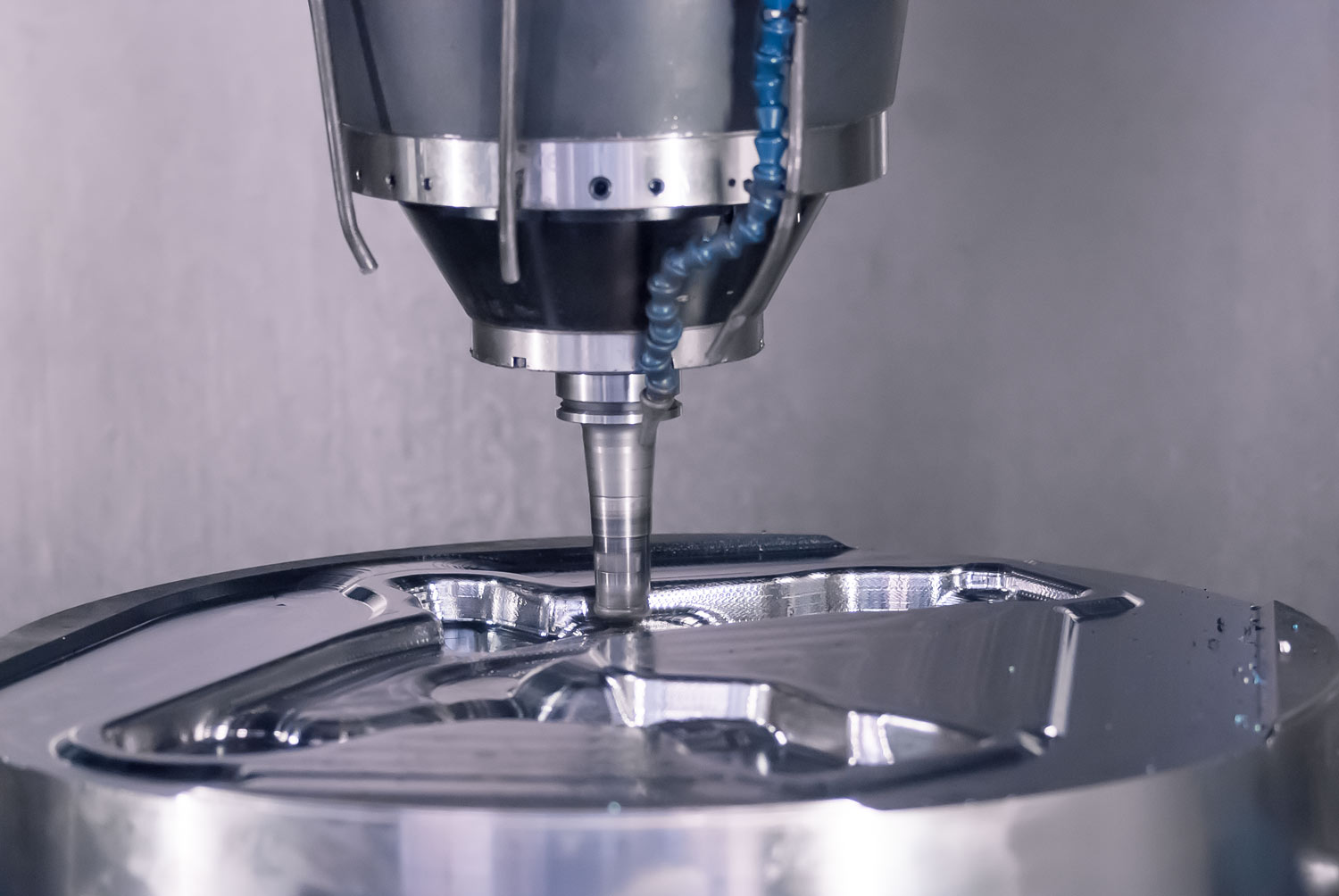

Once the dies have been designed, the next step is their manufacture, which again takes place entirely within the VARESINA STAMPI’S operational structure. At this stage, the die drawings are transmitted to the CAM offices for the toolpath construction.

LET’S START WITH DIES

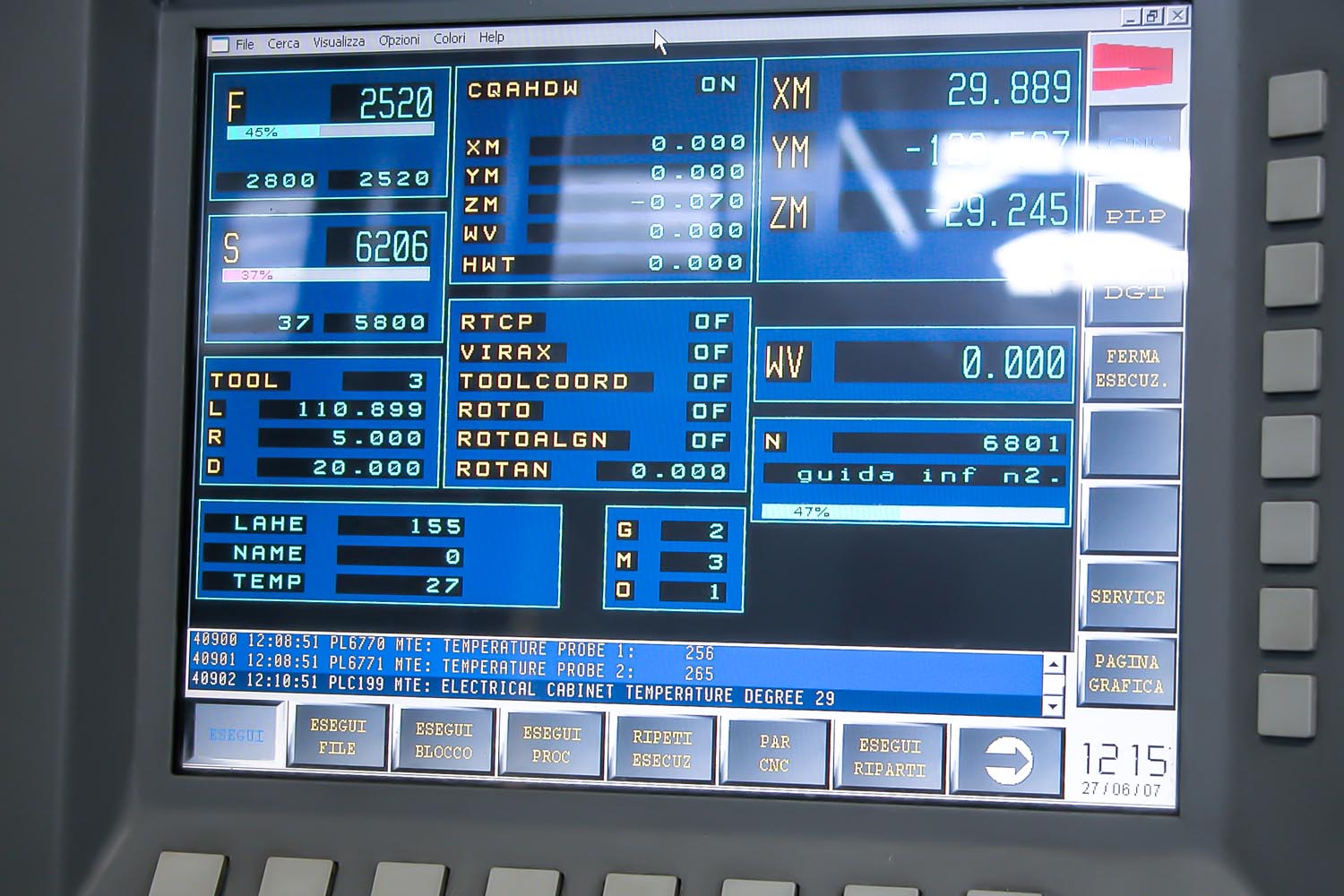

At this point, the workshop receives all the instructions from the technical department indicating the methods and materials to be used. It then proceeds to make the dies using state-of-the-art CNC centres that are located throughout the various production facilities.

CONTACT US

Varesina Stampi S.p.A.

Management and Works in Sumirago

Via Pozzi, 13 – 21040 Sumirago (VA)

Email: sales@varesina.com

Tel +39.0331.909010

DISCOVER THE STAGES OF THE PRODUCTION

>>>>

Dies Design

CAD systems and hot steel stamping simulation

>>>>

Dies Production

Automated CAM systems with CNC machining centres and lathes

>>>>

Hot Steel Drop Forging

Production lines with induction furnaces, presses, hammers and fly presses

>>>>

Heat Treatment

Fully automated oven lines

>>>>

Precision Machining

Machining and finishing