A STRATEGIC ACTIVITY

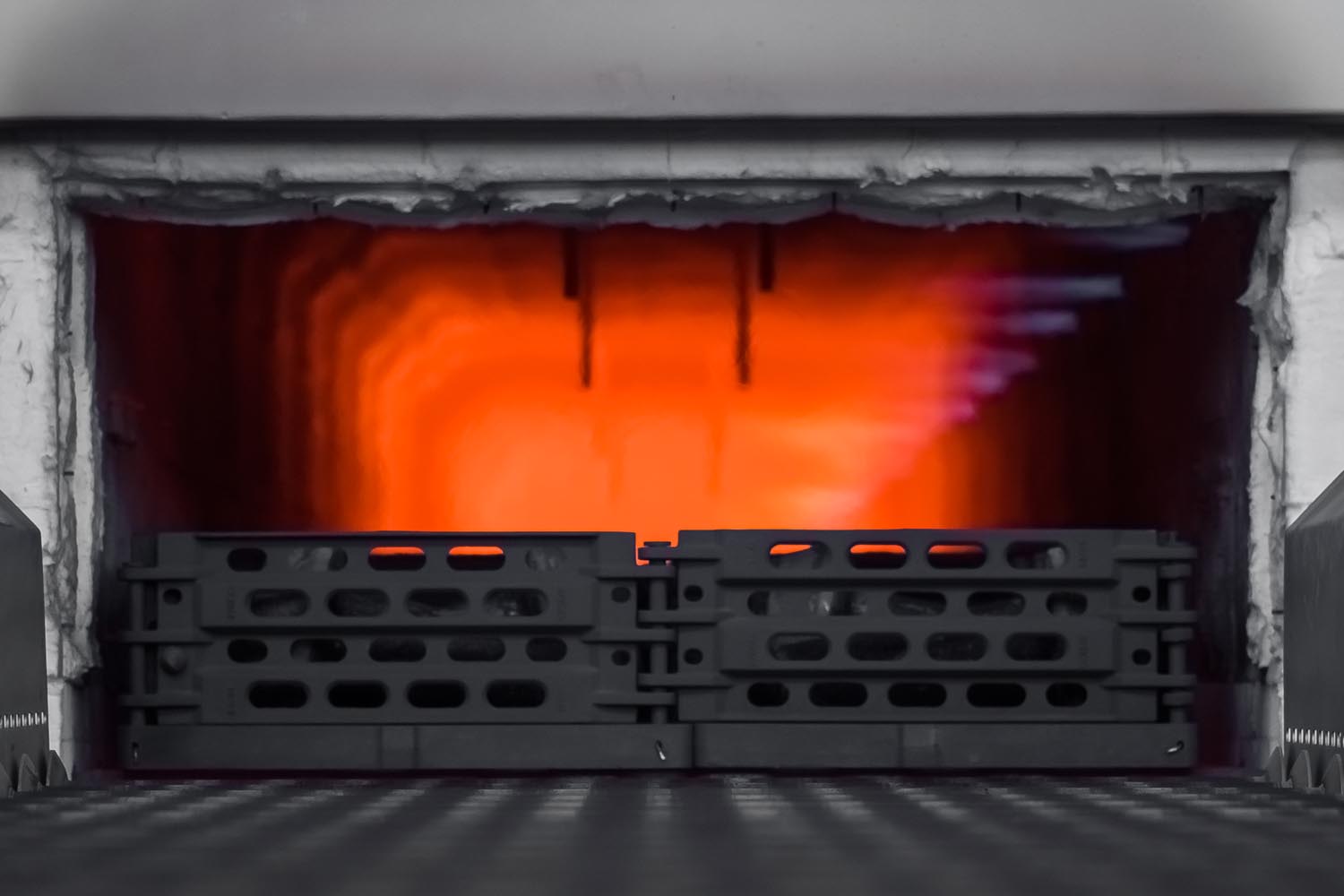

The process of heat treatment of forgings is the most recent activity to be introduced into the VARESINA STAMPI’S line-up. It completes the production process in an ideal and highly strategic way, allowing the company complete independence from external third-party suppliers and therefore guaranteeing maximum production efficiency and enabling it to respond flexibly and promptly to customer requirements.

HIGH QUALITY AT THE CUSTOMER'S DISPOSAL

It is of great importance to emphasise that the heat treatment plant has been approved by several important European customers in the automotive sector. Morever, each phase is subject to regular checks thanks to the decisive support of the in-house laboratory, which is able to carry out a wide array of technological tests, metallographic examinations and specific checks at the customer's request.

CONTACT US

Varesina Stampi S.p.A.

Management and Works in Sumirago

Via Pozzi, 13 – 21040 Sumirago (VA)

Email: sales@varesina.com

Tel +39.0331.909010